Using a 2nd IMU: Difference between revisions

Tag: Undo |

|||

| Line 19: | Line 19: | ||

In order to make use of the 2nd IMU, it needs to be explicitly activated, see [[#IMU Configuration|IMU Configuration]]. | In order to make use of the 2nd IMU, it needs to be explicitly activated, see [[#IMU Configuration|IMU Configuration]]. | ||

{{COMMENT|The on-board mpu6050 IMU is connected to the I2C#2 connector internally and is set to a non default I2C address. If you connect an external I2C-based IMU to the I2C#2 connector, then it can be recognized by its default I2C address, and is used instead of the on-board IMU.}} | {{COMMENT|The newer STorM32 boards like the v3.3 board don't support I2C-based IMUs and don't have a I2C#2 connector.}} | ||

{{COMMENT|On the v1.3 STorM32 boards the on-board mpu6050 IMU is connected to the I2C#2 connector internally and is set to a non default I2C address. That's how it works: If you connect an external I2C-based IMU to the I2C#2 connector, then it can be recognized by its default I2C address, and is used instead of the on-board IMU.}} | |||

[[File:Storm32-wiki-2nd-imu-configurations.jpg|640px|center]] | [[File:Storm32-wiki-2nd-imu-configurations.jpg|640px|center]] | ||

Revision as of 09:35, 1 January 2020

The STorM32 controller allows the use of a second IMU (2nd IMU), in addition to the camera IMU mounted to the camera platform, for superior performance. It's usage and advantages are described here.

Installation Options

The primary rule for installation is:

The 2nd IMU must be mounted such that it is not moved by any of the motors.

It typically is mounted on the gimbal support above the yaw motor. It must not be mounted on one of the gimbal arms or the camera platform.

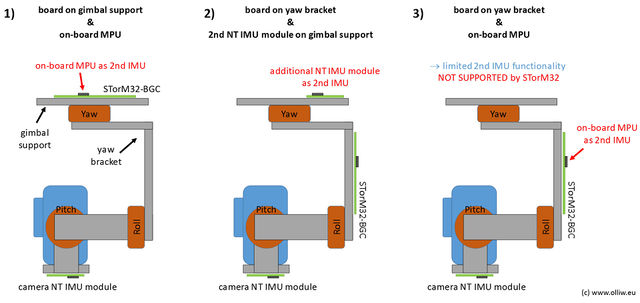

So, you can either mount the STorM32 controller board on the gimbal support, and then use the on-board IMU as 2nd IMU, or you put the controller board somewhere else (on the yaw axis for example) and mount an external IMU module above the yaw motor. These two options are shown as option (1) and (2) in the diagram below. Option (3) is not supported by the STorM32.

The external IMU module can be either a NT IMU module or a "traditional" I2C-based MPU6050 board. The NT IMU module would be connected, like all NT modules, to the NT bus. Its ID solder bridge must be closed (for its location see Pins and Connectors of NT Modules). An external I2C-based IMU would be connected to the I2C#2 connector on the bottom of the STorM32 board.

Which IMU is selected as 2nd IMU is determined by the STorM32 controller as follows:

- If a NT IMU module configured as Imu2 (ID solder pad closed) is found on the NT bus, then it will be used as 2nd IMU.

- If a NT IMU module is not found, but an I2C-based IMU is found at the I2C#2 connector, then it will be used as 2nd IMU.

- If neither of the above, then the on-board IMU will be used as 2nd IMU.

In order to make use of the 2nd IMU, it needs to be explicitly activated, see IMU Configuration.

Comment: The newer STorM32 boards like the v3.3 board don't support I2C-based IMUs and don't have a I2C#2 connector.

Comment: On the v1.3 STorM32 boards the on-board mpu6050 IMU is connected to the I2C#2 connector internally and is set to a non default I2C address. That's how it works: If you connect an external I2C-based IMU to the I2C#2 connector, then it can be recognized by its default I2C address, and is used instead of the on-board IMU.

Calibration

As with the camera IMU, also the 2nd IMU, be it the on-board IMU or an external IMU module, needs to be calibrated for optimal performance.

However, fortunately, for the 2nd IMU it's not critical to get the most accurate calibration, and a good 1-point calibration should be enough for most situations. Exceptions are then motors with high motor pole counts, larger than 14, are used.

The calibration of the 2nd IMU works similar to the camera IMU; one just has to select the 2nd IMU in the respective fields.

IMU Orientation

For a correct functioning it is very important to set the IMU orientation correctly, i.e., the parameter field Imu2 Orientation in the [GUI:Gimbal Configuration] tab.

This is most conveniently achieved by using the [GUI:Configure Gimbal Tool]. Alternatively, it may be set manually following the recipe described in Manually Setting the IMU Orientation.

Yaw Axis Alignment

It is also very important to ensure that at startup the camera is aligned properly with respect to the gimbal support; it needs to point forward to within a degree or so.

This is most conveniently achieved by using the [GUI:Configure Gimbal Tool], which in one step allows you to adjust the camera orientation. Alternatively, the yaw axis orientation at startup may be adjusted manually by setting the Yaw Startup Motor Pos parameter in the [GUI:Gimbal Configuration] tab.

Comment: It is not required to orient the camera precisely by hand before the controller is switched on. Here it is sufficient to have the camera aligned to within typically +-25° (for a 14 pole yaw motor). However, when the controller is powered up, it first moves the motors to default startup positions, and after this step the camera must precisely point to the forward.

IMU Configuration

The 2nd IMU support is determined by the parameter Imu2 Configuration found in the [GUI:Setup] tab. To activate the 2nd IMU, set it to

- “full”: activate 2nd IMU above the yaw motor

- “full xy”: activate 2nd IMU above the yaw motor, with the IMU rotated by 45°.

PID Tuning

The initial PID tuning should be done with the 2nd IMU deactivated.

If, after the initial PID tuning, the 2nd IMU is activated, then the gimbal often works "out of the box", but sometimes the PID values might have to be slightly readjusted. The reasons are the imperfections in the gimbal, such as the balance, the motor quality or insufficiently stiff gimbal arms. With the 2nd IMU activated the controller is much faster and can compensate gimbal motions much better, as a view on the [GUI:DataDisplay] impressively demonstrates. The downside is that imperfections get amplified. Especially the balance of the yaw axis and play in the motor bearings are typical culprits.

If these points cannot be further improved, it can be very successful to down-tune the roll and yaw PID controllers, i.e., to reduce their values. You need to experiment. The control precision is then reduced, but since with 2nd IMU it is much higher anyhow it overall will be still better.

Further points to try is to test different values for Gyro LPF, and/or change the Motor Vmax values by some digits.

Benefits of a 2nd IMU

Nowadays advanced brushless gimbal controller provide 2nd IMU support, but there are marked differences in how and to what extend the 2nd IMU is used. The STorM32 controller is - to the best of the knowledge of the firmware author - unique in that it provides (i) a stable operation with the 2nd IMU above the yaw motor and (ii) a distortion rejection for the yaw axis also in the pan/follow mode. Usually these features would require the installation of a poti or angle encoder on yaw.

The benefits provided by the STorM32's 2nd IMU support are

- significantly improved accuracy, i.e., the camera is held in position with a much smaller error bandwidth

- drastically larger range of operation, essentially any pitch and yaw angle is possible (for a more detailed discussion of the possibilities and limitations see here)

- stable operation of the 2nd IMU above the yaw axis without deterioration over time due to gyro drift

- returns to the correct yaw orientation after an external distortion, also when in pan/follow mode

These features were demonstrated in this video for an early test version of the firmware (the features became better since then):